FAQ

Looking for answers? Here you’ll find the most common questions about our hygienic solutions and how we can support your needs.

Additional questions?

Ask usWhat is the most hygienic material for food industry changing rooms?

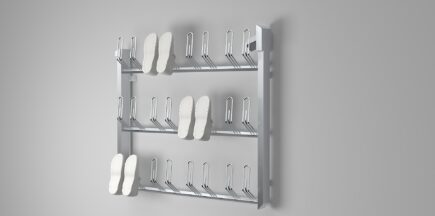

Stainless steel is non-porous, corrosion-resistant, and easy to clean, making it ideal for environments where hygiene is critical. Unlike plastic or coated materials, it withstands frequent sanitation without degrading, ensuring long-term durability and compliance with food safety standards.

What is the best way to clean stainless steel equipment in hygiene areas?

Stainless steel should be cleaned with non-corrosive disinfectants and warm water, followed by drying to prevent water stains. Smooth, non-porous surfaces allow for quick and thorough sanitation without trapping bacteria.

What is the purpose of a sluice entry zone in a food factory?

Sluice zones enforce hygiene protocols before personnel enter high-care areas. They include handwashing stations, boot washers, and controlled access points to prevent contamination. One-way flow systems, such as turnstiles and airlocks, ensure proper procedures are followed.

How do I ensure compliance with food hygiene regulations?

Using stainless steel fixtures, implementing strict hygiene protocols, and designing spaces for easy sanitation all help maintain compliance. Regular staff training and routine cleaning ensure that hygiene standards are consistently met.

How do hygiene zones impact food safety audits?

Well-designed hygiene zones, including sluice entry areas and stainless steel fixtures, demonstrate compliance with HACCP, BRC, and other food safety certifications. A structured personnel flow and documented cleaning processes improve audit readiness and operational efficiency.