NTF Process

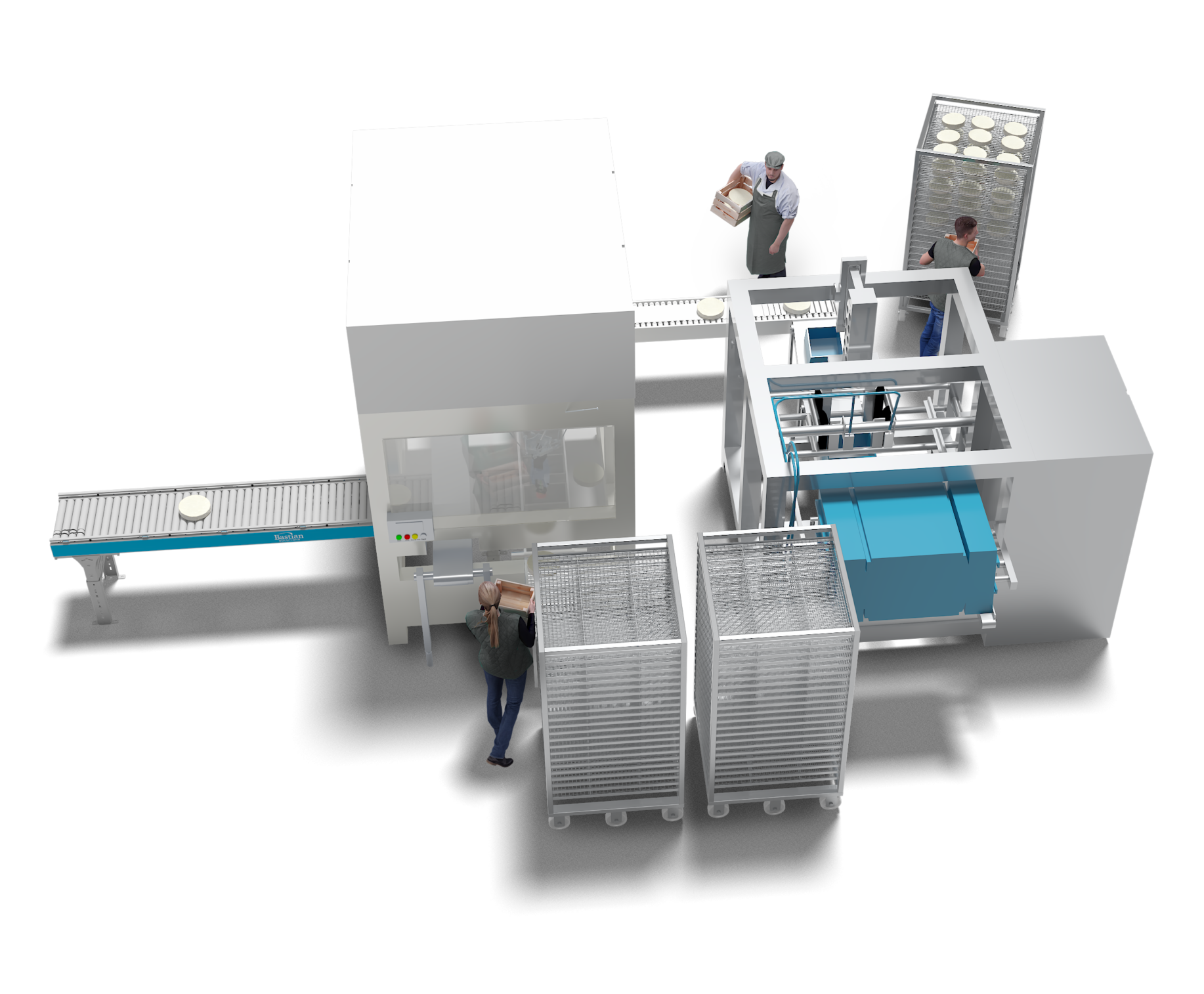

NTF Process is designed specifically for the food industry, ensuring high-quality, hygienic products that meet strict cleanliness standards and are built to last.

Explore our process equipment in wire gratings, wire baskets, processing grids, shelf trolleys, smoke trucks and suspension solutions developed for smoking, cooking, pasteurization, freezing, thawing, etc.